CNC machines are said to be the devices of the future, and thousands of manufacturing businesses all over the world are implementing them in their production process. If you were wondering if you should get these devices, you’ve come to the right place. In this article, we are going to list some of the reasons why a CNC machine is a good investment.

1. They will help you save money

Automating the manufacturing process is a must if you don’t want to spend too much money; if you don’t want to risk losing profits, and if you want to make sure that you have full use of your raw materials.

Since these devices are extremely accurate, they will reduce the overall waste significantly, and by that, they will help you save a lot on costs. In addition, your workers will be more productive, you can manufacture more items per month, and you will make bigger profits.

2. They will promote a safer environment

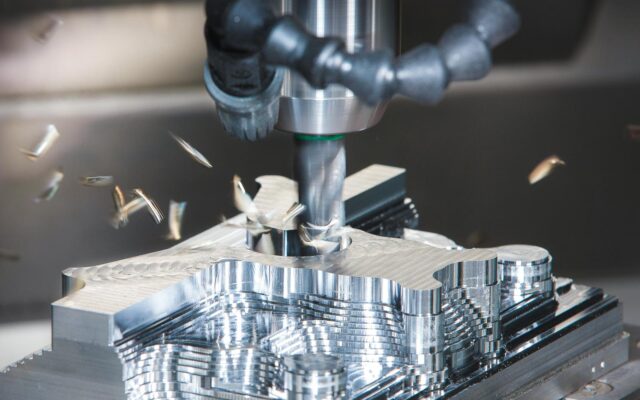

The fact that these devices are made to be automated means that there is no need for personnel, and you don’t have to risk your worker’s health or safety and make them do the drilling and cutting on their own.

When you invest in these devices, your human crew will not be involved in high-risk situations, and they will be less likely to get hurt or injured. Note that the devices can do most of the things on their own, and the only thing you will need to worry about is choosing the right model, and programming it in the way that you want.

3. They are going to help increase the production speed

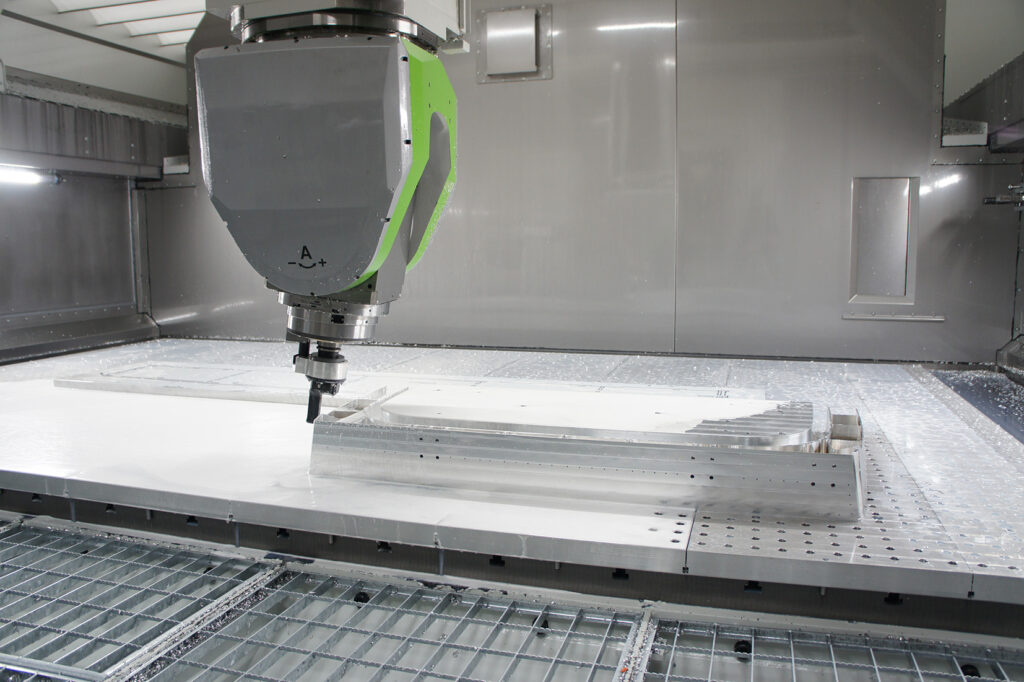

When we think about the production process, we think about thousands of items that are created daily, without any delays, errors, or issues. When you implement these devices in your company, you will be able to create a lot of items at the same time, and with that, you will satisfy your customers’ needs.

On websites like elephant-cnc.com, you can see that the automated CNC machines can produce high-end customized goods, and you can choose the best device for you depending on your current needs.

We never want to tell our clients that the items they need are still being manufactured, and we don’t want to force them to go to our competitors just because we don’t have enough goods. These machines reduce the number of steps that are needed during manufacturing, and with that, they can create items better and faster.

4. They are going to help you create better products

When you choose to implement CNC machines into your production process, they are going to help you create better products, and ultimately, your customers will be much more satisfied. Note that with these devices, you can create better moldings, and you can pay bigger attention to details.

In addition, you will be able to reduce mistakes and errors, and you won’t have to deal with faulty products. Everything from the beginning phases, up to the finishing product will be properly implemented and created, and you will end up with perfect products. Note that even the most skilled and experienced technician is bound to make mistakes, whereas machines can be programmed to avoid those errors.

Pick the right model for your needs, and know that pretty much everything is customizable, so you can easily create any products that will make your customers happier and more interested in investing in your brand.