What Is Chemical Etching?

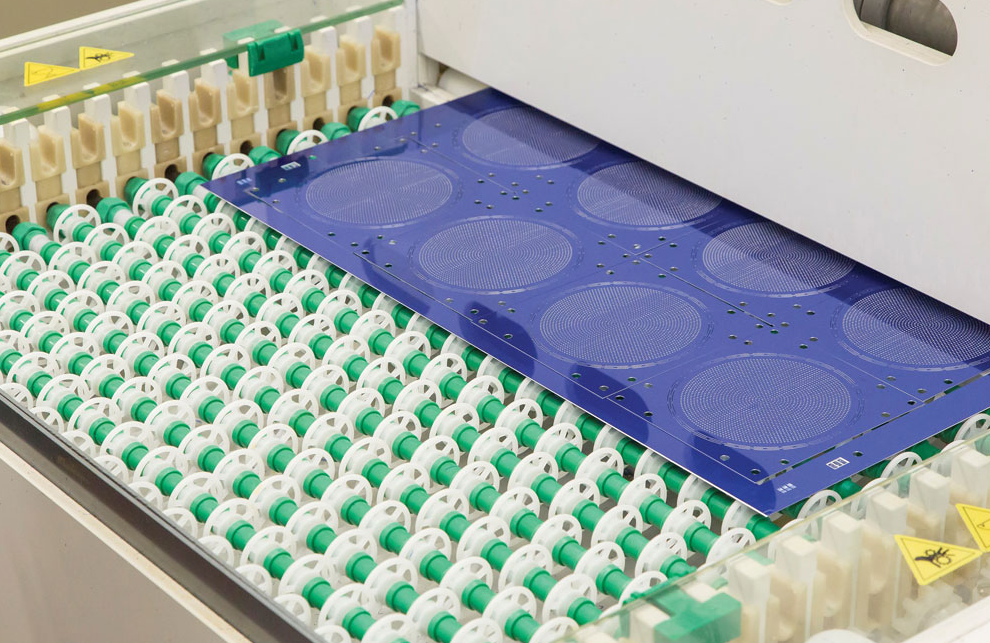

Chemical etching can be described as a metal fabrication process for thin metals with simple or complex designs. Also referred to as photo etching or chemical machining, chemical etching is a process with several steps that use photosynthesis material to move parts into metal sheets.

New and modern technologies like automation, electric vehicles, drones, medical devices, and hydraulic energy need smaller metal components devoid of errors. This is where photochemical etching comes in. It is a great alternative for what is popularly referred to as stamping and lesser cutting.

Benefits of chemical etching for engineers:

It is a flexible and affordable tool

Prototyping is a very important part of the design process. Prototyping usually involves going through multiple interactions before settling on a single final design. It can be extremely expensive when using stamping to produce parts instead of chemical etching. Other than being expensive, stamping or lesser cutting is a very slow process. The good thing about digital tooling is that they are produced in a matter of hours compared to conventional techniques that take weeks.

Metal properties unaltered

There’s no force or heat used during the chemical etching process. This means that the intended purposes of the part won’t be affected in any way. High temperatures and hard tooling can easily cause the material to warp or expand because of their excessive effects on thin metal. But photochemical etching ensures all parts remain flat throughout the invasive process while at the same time achieving great results.

Low dimensional tolerance

Holding low tolerance is vital for parts to be able to interact with other components. Photo etching is widely known for its low dimensional tolerance with any type of metal and the most complicated designs. That is why most people prefer using the chemical etching process in their production tasks.

Complex designs

It is easy to achieve complex designs when using the photo etching process. Photo etching generally with a metal that has been assigned an image and chemically treated to produce a black-and-white negative of the desired picture.

Wire EDM or lesser cutting is much slower since they are only able to only cut one feature at a time. Besides, the process leads to heat-affected zones (HAZ) within certain areas. This is not something you can experience when photochemical etching is used. This is because the method runs all the features simultaneously.

How Does Chemical Etching Compare to Other Processes?

Manufacturing processes are different in many ways. Their strengths largely depend on what exactly you are designing. How does one determine which one will perfectly work for the upcoming project? What material will you need? What is the right amount of heat or pressure to apply? These are just some of the questions that you need to ask yourself before getting started with photochemical etching.

When it comes to the material to be used, the use of aluminum has significantly increased in metal fabrication. The same applies to copper and stainless steel.