Plasma cutting is a process that uses an electron beam to cut metal. It is a fast and accurate way to make precise cuts, and it is becoming increasingly popular because of its versatility and accuracy. In this article, we will explore the basics of plasma cutting and see how it works.

In a plasma cutting process, an electron beam is used to cut metal. The electron beam is extremely powerful, and it can cut through metal very quickly and with great accuracy. This makes plasma cutting a very versatile tool, and it can be used to make a variety of cuts and shapes.

One major advantage of plasma cutting is its speed. Plasma cutting service can be incredibly fast, and it can easily cut through metal materials. This makes it an ideal choice for applications that require quick and accurate cuts.

Another benefit of plasma cutting is its accuracy. Plasma cutting is highly accurate, and it can produce precise cuts without any errors. This makes it a great choice for applications that require high-quality cuts.

Overall, plasma cutting is an efficient and versatile tool that is becoming increasingly popular due to its speed and accuracy. If you are looking for a fast and accurate way to make precise cuts in metal, then plasma cutting may be the perfect option for you.

What is Plasma Cutting?

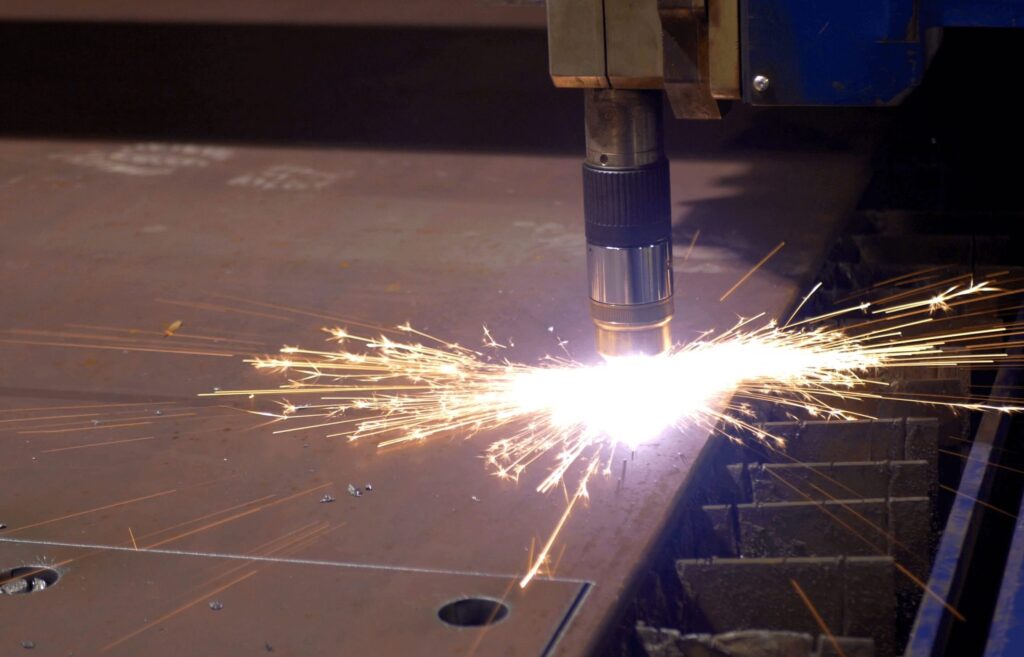

Plasma Cutting is a process that uses a high-energy beam of plasma to cut materials. This process is different from traditional machining because the plasma cutter cuts through the material using a sustained, very high-temperature and high-pressure beam. The high temperature and pressure cause the material to vaporize, or turn into gas, which then forms an aerosol that is drawn up into the cutting nozzle. This allows the cutter to quickly and easily cut through a variety of materials.

The benefits of using a plasma cutter include its precision and speed. Because the cutter is able to quickly vaporize the material, it is able to achieve very accurate cuts. Additionally, the high temperature and pressure allows the cutter to cut through tough materials such as metals and plastics with ease.

How Does Plasma Cutting Work?

Plasma cutting is a process where a plasma torch is used to cut through materials. The heat and energy of the plasma torch melts the material and then the plasma cutter uses a rotating wheel to shave off the desired pieces. This process is often used to cut through hard materials like metal or plastic, as it can create much cleaner cuts than traditional methods like manual tools or saws.

Plasma cutting is a very fast and efficient process, and it can be used to cut a variety of materials including metal, plastic, and even wood. It is also a very clean process, which means that it can be used to create cuts that are free from debris or other contaminants.

There are a number of different plasma cutting machines on the market, and each one has its own unique features and capabilities. It is important to choose the right machine for the task at hand, as different machines are best suited for different types of cuts.

Benefits of Plasma Cutting

Plasma cutting is a process that uses a gas-fired torch to cut materials by combining heat, flame, and air. Plasma cutting can be used for a variety of applications, including manufacturing, engineering, and construction. Here are some of the benefits of plasma cutting:

- It is an efficient way to cut materials.

- It is an environmentally friendly process.

- It is a fast process.

- It can be used in a variety of applications.

Who Needs Plasma Cutting?

Plasma cutting is a process that uses a high-energy plasma to cut materials quickly and easily. It’s often used in the manufacturing and construction industries, where it can be used to cut metals, plastics, and other materials. Plasma cutting is also becoming increasingly popular in the home improvement industry, as it can be used to create custom cuts and openings in wood, tile, and other materials.

Who Provides Plasma Cutting?

Plasma cutting is a process that uses a high-energy plasma torch to cut through materials. It is most commonly used in the manufacturing of products such as furniture, boxes, and aircraft parts. Plasma cutting is typically performed by specialized companies that have the necessary equipment and expertise.

How Plasma Cutter Works

Plasma cutting is a process that uses a high-velocity gas to cut through materials. The gas creates a hot, ionized plasma that cuts the material like a knife. This process is used in a variety of industries, including aerospace and defense, automotive manufacturing, and furniture making.

Plasma cutting is an efficient way to make cuts through difficult materials. It is also faster and safer than other cutting methods, like manual sawing or knife grinding.

Plasma cutting works by heating up the material until it vaporizes. This vaporized material then forms a plasma that cuts through the material like a hot blade.

Downsides of Plasma Cutting

The advantages of plasma cutting are vast, but it comes with some significant disadvantages as well. Here are five of the most common ones:

- It’s Dangerous: Plasma cutting is a very dangerous process, and it can easily cause burns and other injuries if not done correctly.

- It’s Time-Consuming: Plasma cutting is time-consuming and can take a lot of time to complete a project.

- It Requires Special Equipment: To use plasma cutting, you need special equipment and knowledge, which means that it won’t be suitable for every project.

- It Can Cause Damage to Your Materials: If your materials are not cut properly or if the plasma cutter overheats, they can be damaged. This can lead to a loss of money and wasted materials.

- It Requires Special Training: To use a plasma cutter safely and effectively, you’ll need some specialized training.