Whether you’re a beginner or have some experience with plasma cutters, it’s important to know how precise they are. After all, you don’t want to make a mistake when cutting metal. Plasma cutters are a great tool for anyone who needs to cut metal. They are safe, easy to use, and very precise. But how precise are they? In this blog post, we will explore the precision of these cutters and how they have changed over the years. We will also provide some tips on how to get the most precise cuts possible.

What is a Plasma Cutter?

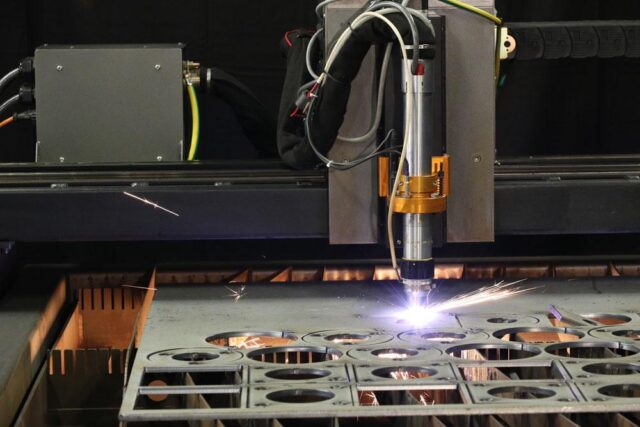

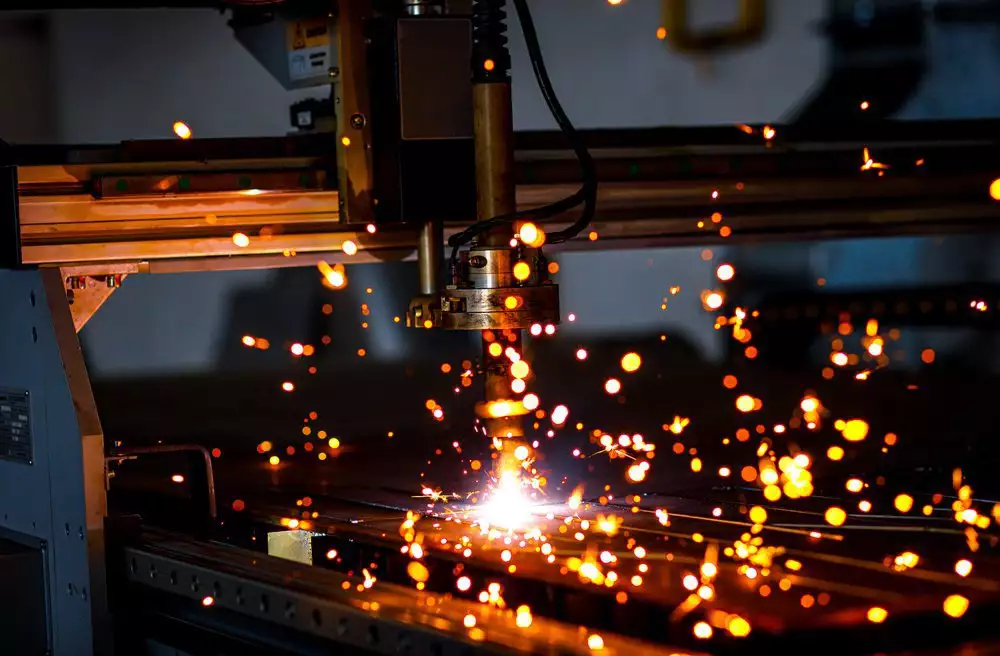

It is a device that uses electricity to cut through metal. The process works by using an electrical arc to heat up a stream of ionized gas, or plasma, which then melts the metal. It can be used to cut through all types of metals, including steel, aluminum, and stainless steel.

There are several advantages of using a plasma cutter over other cutting methods.

– First, it can cut through thicker materials than other machines such as oxy-fuel torches.

– Second, the cuts made by a plasma cutter are usually cleaner and more precise than those made by other methods.

– Finally, it can be used on a variety of different materials, making it a versatile tool for any workshop.

How Precise is a Plasma Cutter?

Some metals are easier to cut than others. For example, aluminum is a soft metal that is easy to cut with a plasma cutter. Stainless steel is a harder metal that is more difficult to cut. The thicker the metal, the more difficult it is to cut with a plasma cutter. The speed of the cut also affects the precision of the cut. A slower cutting speed will result in a more precise cut, while a faster one will result in a less precise cut. Finally, the quality of the cutter also affects its precision. A high-quality cutter will be more precise than a low-quality one.

Pros and Cons of Using a Plasma Cutter

Plasma cutters are a great way to make precise, clean cuts in metal. However, there are some things to consider before using one. Here are the pros and cons of using it:

Pros:

– Precise: They can make very precise cuts, which is why they’re often used in manufacturing and other industries where accuracy is critical.

– Fast: They can cut through metal very quickly, making them ideal for projects where time is of the essence.

– Versatile: They can be used on a variety of different materials, including aluminum, stainless steel, and even thick plate steel.

Cons:

– Expensive: They can be quite expensive, so they may not be the best option for those working on a budget.

– Dangerous: They use high temperatures and electrical currents, which can be dangerous if not used properly. Always follow safety guidelines when using a plasma cutter.

Plasma cutting services are a great way to make precise, clean cuts in metal

What Materials Can Be Cut with a Plasma Cutter?

There are a few different types of materials that can be cut with a plasma cutter including:

– Thick metal: It can easily cut through thick metal, making it a great tool for those who work with this type of material on a regular basis.

– Pipe: If you need to cut through a pipe, a plasma cutter can make quick work of it.

– Aluminum: While aluminum isn’t as thick as metal, it can still be difficult to cut through. A plasma cutter can make light work of cutting through aluminum.

How to Use a Plasma Cutter?

There are two types of cutters: handheld and machine-mounted. Handheld units are smaller and less expensive, but they can be difficult to control and are not as precise as machine-mounted units. Machine-mounted units are more expensive, but they offer greater precision and easier controls.

When using a plasma cutter, it is important to wear protective clothing and safety goggles. The sparks generated by the cutter can cause serious injury if they come into contact with your skin or eyes. It is also important to work in a well-ventilated area to avoid inhaling the fumes generated by the cutter.

– To use a handheld plasma cutter, hold the unit in one hand and position the tip of the cutter against the metal you want to cut. Squeeze the trigger to activate the flow of plasma, then move the tip along the line you want to cut. To make curved cuts, tilt the tip of the cutter up or down as needed.

– Machine-mounted plasma cutters are operated differently than handheld units. Typically, you will need to place the metal you want to cut onto a cutting table or surface. Position the cutting head over the metal, then squeeze the trigger to activate the flow of plasma. The cutting head will automatically follow the contours of the metal, making it easy to create complex shapes and designs.

Safety Tips for Using a Plasma Cutter

When using these cutters, it is important to take safety precautions. Here are some safety tips to keep in mind:

– Wear proper safety gear – You should wear proper safety gear, including gloves, goggles, and a face shield.

– Be aware of your surroundings – Make sure there is no flammable material nearby that could catch fire.

– Follow the instructions – Be sure to read and follow the instructions for your particular model of plasma cutter.

Alternatives to Using a Plasma Cutter

If you need to make a clean, precise cut but don’t have access to a plasma cutter, there are a few other options you can try. A jigsaw or power saw can be used to make rough cuts, while a handheld rotary tool with a cutting accessory can be used for more detailed work. If you’re working with metal, you can also use a hacksaw or angle grinder to make cuts, though these will likely be less precise than those made with a plasma cutter.

Conclusion

A plasma cutter is a versatile tool that can be used for a variety of tasks, from cutting through thick metal to engraving delicate designs. Some cutters are more accurate than others, but in general, they are all pretty precise. So, if you need a tool that can give you clean, precise cuts, then a plasma cutter is definitely worth considering.