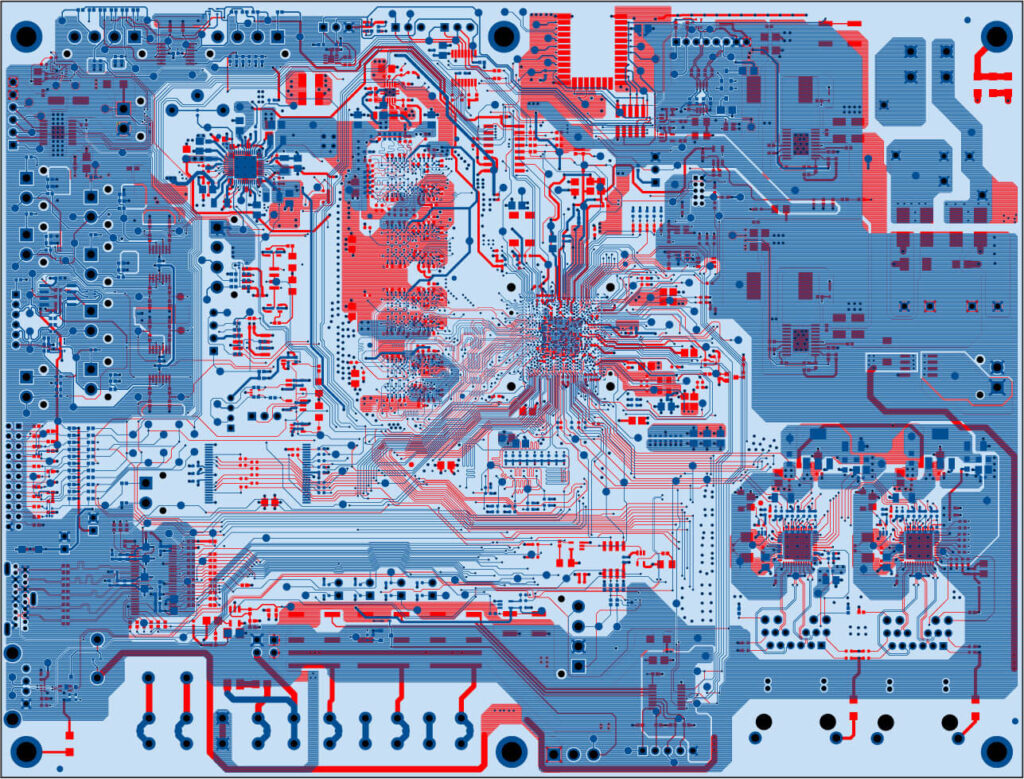

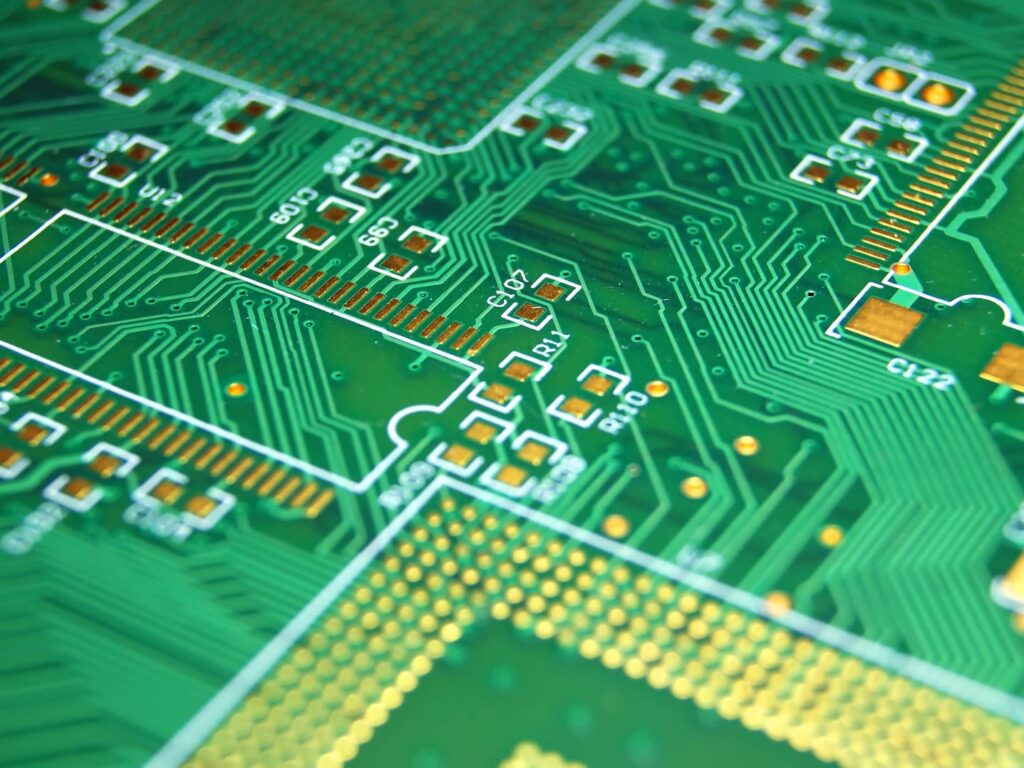

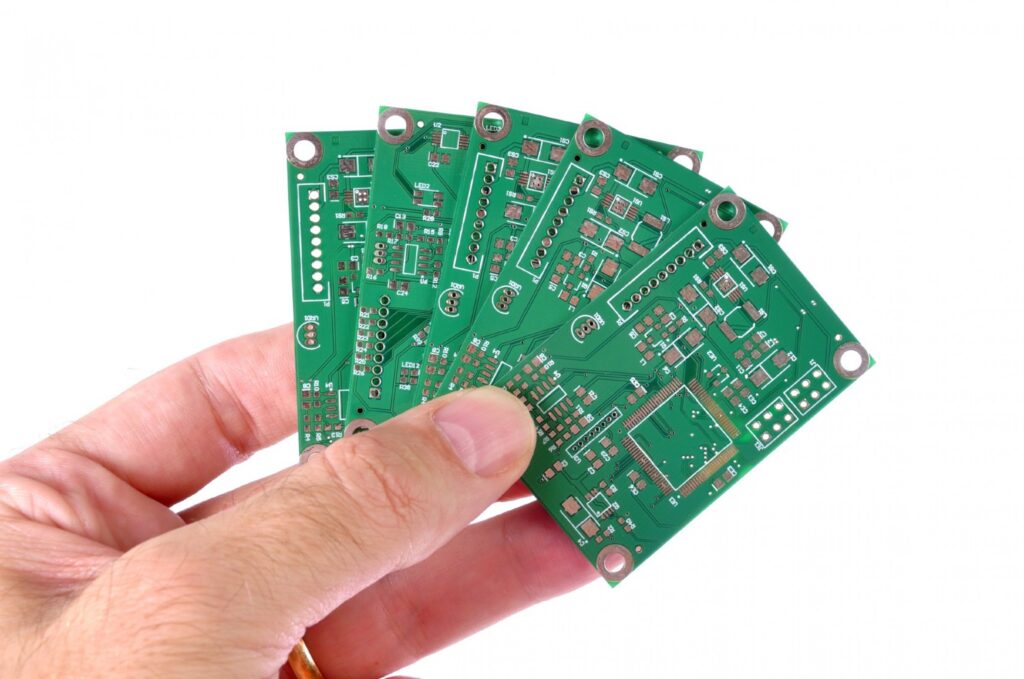

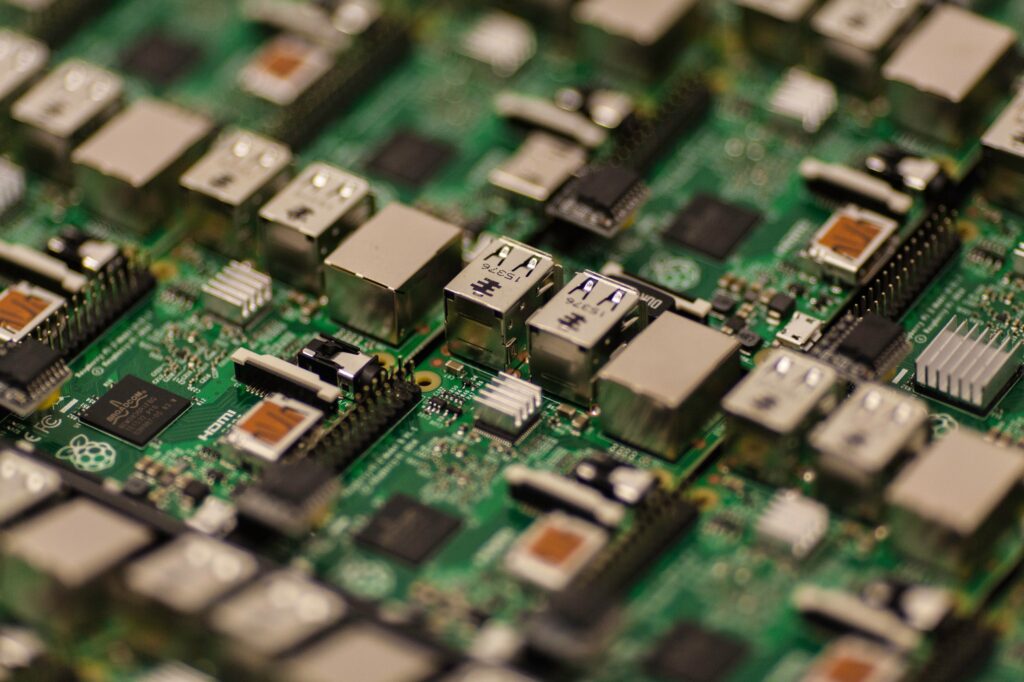

Nowadays, making electronic devices would be impossible without printed circuit boards. This small electronic board is of great importance because without it – it wouldn’t be possible to establish a connection between the electrical components on any device. Printed circuit boards can be made by hand or by machine. If you are a fan of electrical engineering and you are still a beginner – here are some tips and tricks for PCB designing.

PCB: A Small Component That Means A Lot

The practical realization of an electronic device is impossible if you do not have certain components. These components can sometimes be very small – but also very important. Printed circuit boards are an excellent example. Namely, PCBs enable the process of connecting all components of an electronic device and make it work as a whole. This type of connection can be accomplished in several ways. Beginners sometimes use pre-made, very simple printed circuits that they can upgrade in time. However, the best solution that all electronics fans come to – is printed, circuit boards. Here, we will briefly mention some of the designing tips that beginners can easily use.

The Importance Of PCBs Design

Fans of electrical engineering are most often focused on the operation of electrical circuits or codes. Due to that, sometimes it happens that they overlook some other important things such as PCB design. This can even be considered the most common mistake when it comes to making electrical appliances. According to uetpcba.com, insufficient attention to the design of the printed circuit board can sometimes cost us more – in the sense that we will have to repeat the whole process later. Therefore, we will give you some basic tips on how to achieve a good PCB design and not get into situations like this.

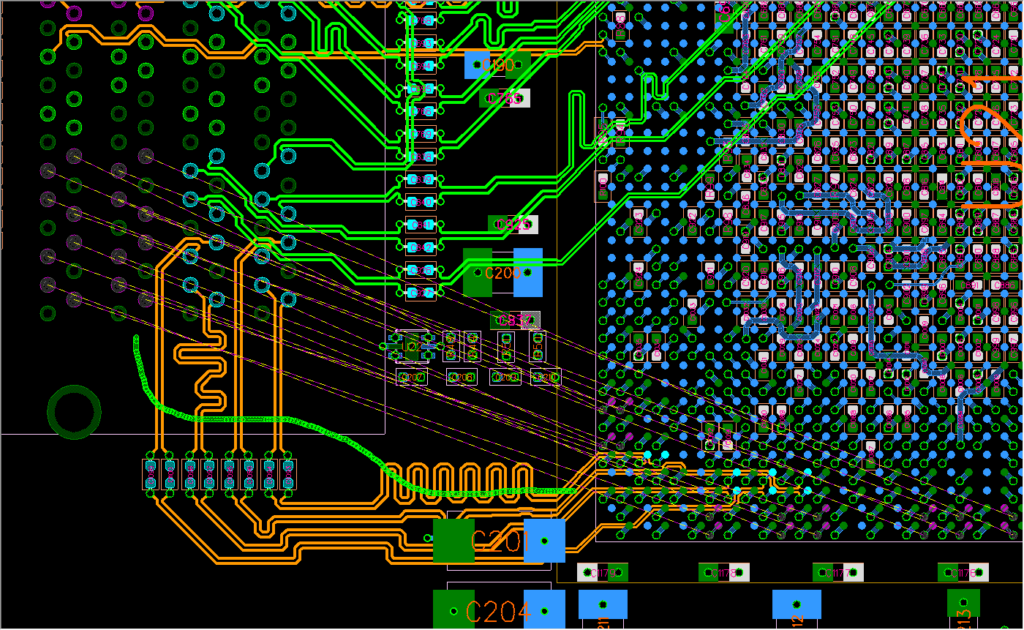

1. Choose The Right Tool To Design PCBs

Before you even start doing anything, make sure you have the right tools. This is one of the most important items when it comes to PCBs design. The tool you use should meet the needs and basic properties when it comes to designing. What is important when choosing – is that the tool you choose is easy to use.

2. Think About The Angle At Which You Design The PCB

This is a thing that experienced PCB designers already know well. Namely, if you design a PCB at an angle of 90 degrees or more – acid deposits may form, which will damage your PCB. On the other hand, too small, narrow angles can lead to electromagnetic radiation. That should be avoided because it also causes the migration of copper from your printed circuit board. Therefore, the best solution is to work at an angle of 45 degrees because you will avoid such problems.

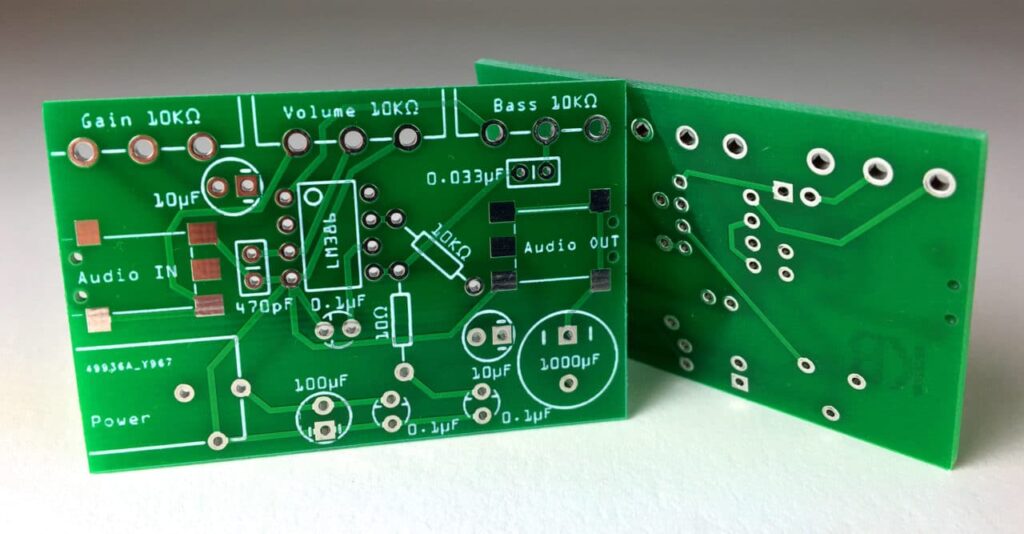

3. When Designing A PCB Don’t Forget The Proper Housing

Before you start designing a PCB, you need to know what its purpose is – that is, what is the final product where you will install your PCB. Very often it happens that we make PCBs – but we don’t have housing for the final product. Therefore, we must be careful because our PCB must match the housing of the product for which it is intended. Therefore, it is recommended that you choose a simple housing – the one it can serve as a template and design a PCB around it. It is possible that such or similar housing will be used – so that way, you will avoid repeating the job.

4. Check Out Your PCB Design Before Installing

In the end, just like with any job done, you have to do a check. In this case, it involves a very thorough visual inspection and identification of possible deficiencies. If you notice any defects, they should be rectified before installing the PCB. Very common shortcomings in PCB design are design deviations, missing components, poor electro-bridging, traces of acid, etc.

The Bottom Line

Whether you are a beginner or have experience designing PCBs – we hope some of these tips and tricks will help you. Of course, you will have the opportunity to raise your work to a better level over time, so the design of the PCB will no longer be a problem.